Product Application Examples SAMPLE

- Laser / optics related equipment, optical alignment

- Precision scanning and mapping measurements

- Objective Lens Focus Applications

- Ultra-precision nano machining / high-speed cut machining

- Various precision positioning applications

- Detection and measurement of minute forces at the ΜN (mg) level

- Highly sensitive force measurement while maintaining high rigidity

- Equipment/Unit Design Fabrication Examples

-

Laser / optics related equipment, optical alignment

-

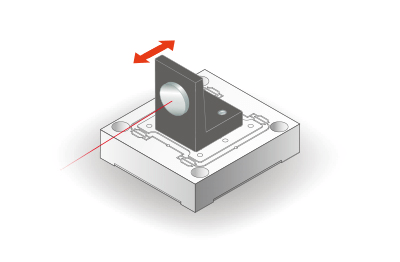

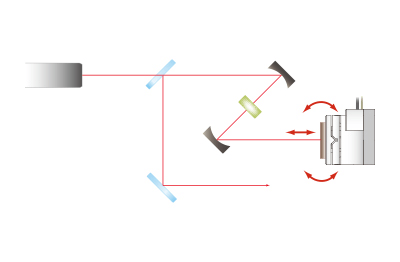

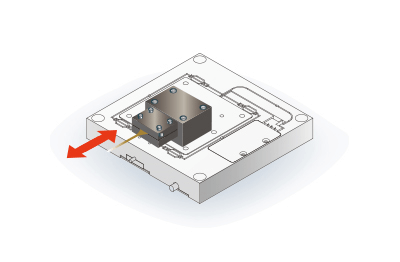

Mirror fine-tuning of interferometer

Mirrors can be controlled with high precision to a fineness of several hundredths of a wavelength, and optical systems using interference can also be measured stably.

-

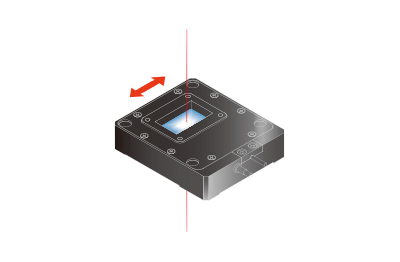

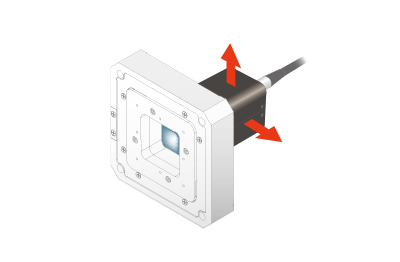

Transmission optical elements alignment

Openings can be easily provided even in a small body, making it suitable for positioning optical devices that transmit laser light, etc.

-

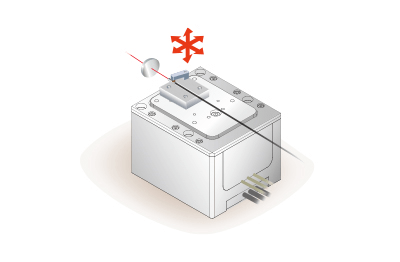

Optical fiber optical axis adjustment

Optical fibers can be aligned with high accuracy and high speed in the XYZ axis, making it easy to find the peak point of incoming light.

-

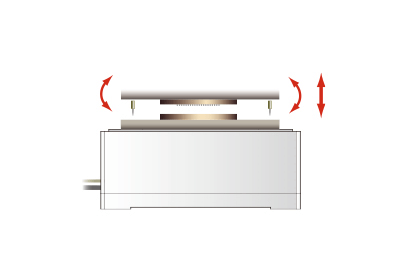

Mirror scanning for laser machining

Designs with water-cooled flow paths are also available to suppress heat generation in the reflecting mirror due to high-power lasers.

-

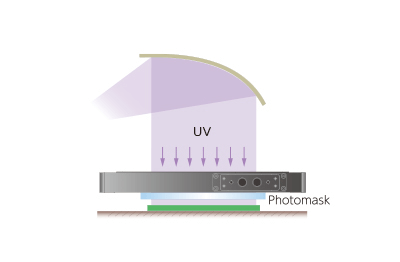

Lithography circuit board alignment

The XY axis stage has a large opening of 200 mm square, allowing circular motion while transmitting light to the glass substrate.

-

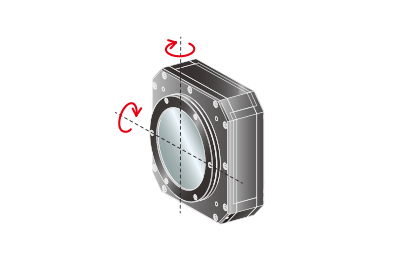

Optical mirror high-precision angle adjustment

The mirror can be fine-tuned in angular resolution on the order of μrad (micro rad), making it optimal for alignment of confocal optics.

-

-

Precision scanning and mapping measurements

-

CCD pixel shift (pixel shift)

It can also be applied to CCD pixel shifting (pixel displacement) used for high-resolution imaging.

-

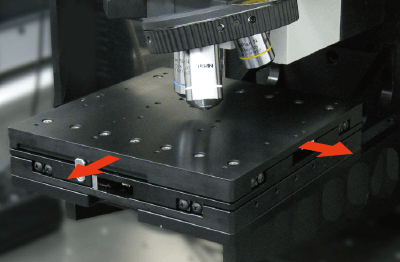

Sample tables for microscopes and analytical instruments

Suitable for use on sample tables of analytical instruments such as Raman and spectroscopy to obtain high-precision 2D mapping images.

-

Probe microscope, AFM/SPM

Closed-loop control using a built-in displacement sensor enables more precise image acquisition and accurate movement to the target position compared to a tube scanner.

-

Mapping Measurement

Ultra-high resolution mapping of small areas by piezo stage and wide range of high precision mapping by piezo motor stage are available.

-

Semiconductor and LCD related equipment

Alignment marks between devices can be aligned with high precision.

-

Nanometer scanning

Smooth and reliable scanning operation that follows command signals such as sinusoidal wave and square wave is possible.

-

-

Objective Lens Focus Applications

-

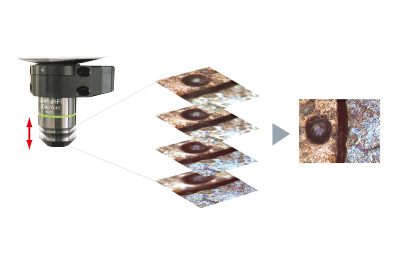

Microscope High Speed Focus

Piezo stages are also suitable for fast AF to follow the undulations of the observation device. Special lenses are also available.

-

Image Processing Application

Real-time images with a deep depth of focus can be obtained by superimposing slice images acquired with a high-speed camera while moving the objective lens at several tens of Hz.

-

Interference form measurement

The high resolution of the piezo stage is also suitable for shape measurement using the principle of interference.

-

Semiconductor and FPD inspection equipment

We offer optimal design using piezoelectric elements to achieve the high precision required by miniaturization and the high speed required by tact time.

-

Laser machining

Focus adjustment of optical lenses in laser processing is also performed with high speed and high precision.

-

Confocal Microscope

The mirror can be fine-tuned back and forth in the nm (nanometer) range and angular fine-tuning in the μrad (micro rad) level with high resolution, making it optimal for alignment of confocal optics.

-

-

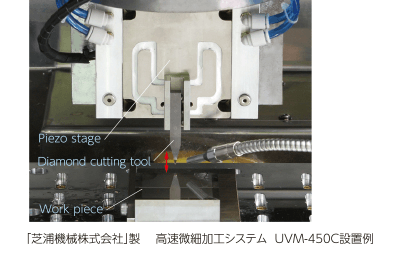

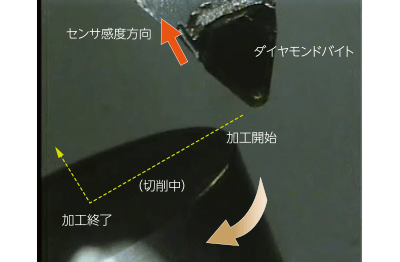

Ultra-precision nano machining / high-speed cut machining

-

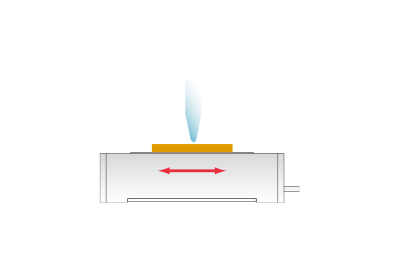

FTS

Ultra-precision machining is achieved by using a piezo stage for fine cutting of tools for faster machining speeds and higher accuracy.

-

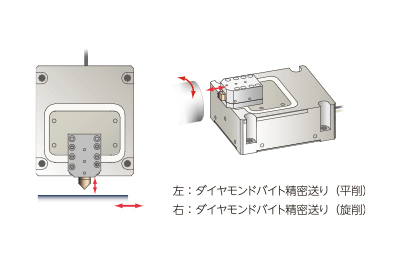

Diamond Turning Tool Precision Feeding

It can also be applied to the machining of non-axisymmetric free-form surfaces that accompany the increasing sophistication of optical devices.

-

Precision die machining

The cutting edge of the tool is precisely aligned with the rotational axis of the workpiece and has the rigidity to maintain a stable posture during machining.

-

Precise positioning of workpieces

It can also be applied to the continuous and repeated movement of the workpiece and punch press.

-

-

Various precision positioning applications

-

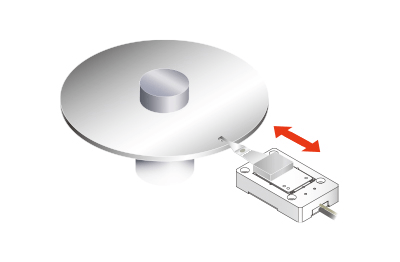

HDD Tester

The magnetic head can be applied to investigation, analysis, etc. by obtaining a signal of the disk while moving with ultra-high accuracy on the piezo stage.

-

Microscopic specimen tensile, compression

Micro specimens are subjected to tension or compression on a piezo stage, which can be applied to acquire data from the elastic range to the plastic range to rupture.

-

High Precision Parallel Surface Alignment

The 2-axis tilting stage enables high-precision plane alignment before pressing.

-

Friction and Wear Test

The piezo stage vibrates the specimen precisely at a fixed period to test the amount of wear on the specimen and the mating material.

-

-

Detection and measurement of minute forces at the μN (mg) level

-

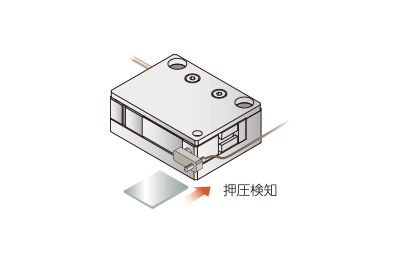

Micro-pressure load measurement

Even minute forces at the μN to mN level can be measured with high sensitivity.

-

Optical fiber and functional devices contact detection

It can also be used as a high-precision touch sensor between devices.

-

Spring Probe Spring Pressure Test Measurement

It is possible to measure with high sensitivity even springs with small elastic force that are difficult to measure with load cells.

-

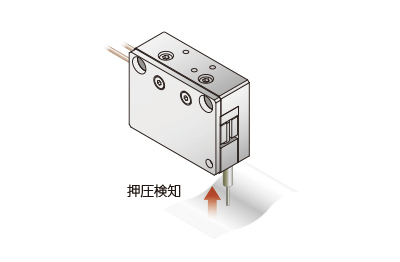

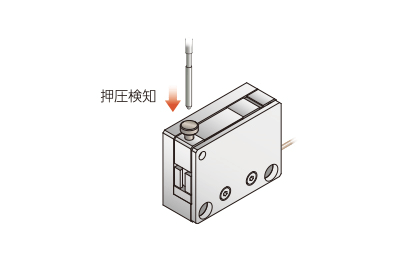

Probing contact detection on semiconductor devices

Probing of device electrode surfaces for failure analysis, etc., also captures the moment of contact with high sensitivity.

-

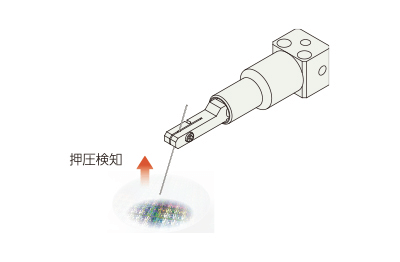

Micro Actuator Thrust Measurement

It can also be applied to thrust inspection and measurement of small motors and actuators.

-

Tensile and rupture force measurement

Tensile and rupture forces of minute specimens such as fibers, which are difficult to measure with ordinary testing equipment, can be measured with high sensitivity.

-

Needle tip puncture force into cells

It measures the puncture force when inserting a needle into a cell, membrane, etc.

-

Micro friction force, thrust monitor

Force applied during peeling of thin films, etc. can be measured.

-

-

Highly sensitive force measurement while maintaining high rigidity

-

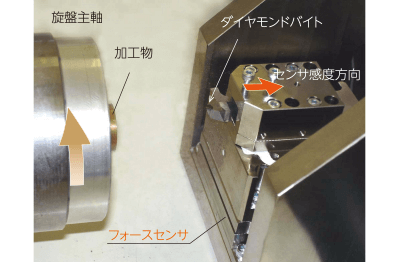

Workpiece and Diamond Turning Tool Contact Load Measurement

The cutting force when the bite tip contacts the rotating workpiece can be measured.

-

Frontal Turning Cutting Resistance Measurement

Detects the force received by the diamond turning tool during the frontal turning process.

-

Cutting and grinding force measurement during precision machining

The grinding wheel measures the state of surface polishing and makes it possible to determine the state of the machining process.

-

Contact detection between bite cutting edge and workpiece

Air cutting time in the proximity of the bite cutting edge and the workpiece can be reduced.

-

Pressure and hardness control

By measuring the reaction force when a certain amount is pressed, it is possible to manage the pressing pressure and reaction force (hardness).

-

Friction force measurement

Pressure can be monitored during pressing.

-

Thrust and Reaction Monitor

It is possible to numerically monitor the thrust of the drive source and the resulting reaction force.

-

-

Equipment/Unit Design Fabrication Examples

-

SAICAS

Cuts from the surface to the interior of the material and evaluates the mechanical characteristics of the material based on

depth and cutting force during the cut.-

Application Examples

Resist film, optical film, plating film, ultra-surface layer of polymer materials, etc. 等

-

Equipment Provision

Daipla Wintes Co., Ltd.

-

-

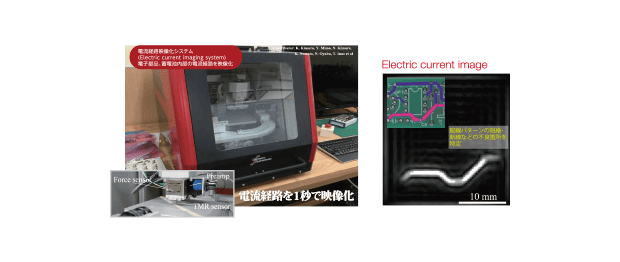

Current path imaging equipment

Non-destructive imaging of batteries and electronic devices

-

Application Examples

・Identification of abnormalities in the internal electrodes of lithium-ion battery packages

・Diagnostic imaging of defective locations on printed circuit boards with complex wiring patterns

・Identification of self-discharge locations -

Equipment Provision

Integral Geometry Science Inc.

-

-